The Advantages of Using In718 Powder in Additive Manufacturing

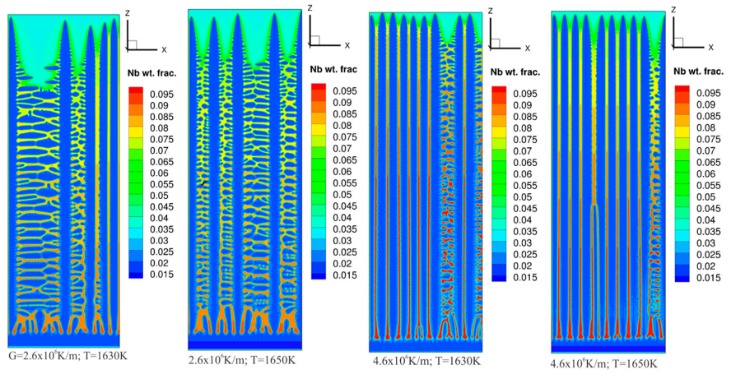

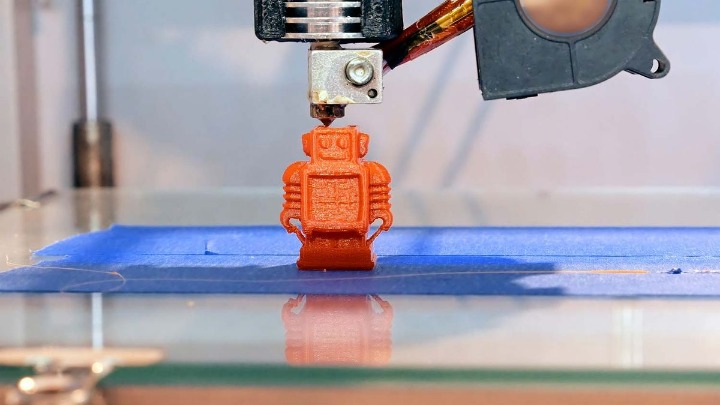

In718 powder is a high-strength nickel alloy powder used in additive manufacturing processes such as 3D printing. This powder is known for its excellent mechanical properties and high-temperature resistance, making it ideal for a wide range of applications in industries such as aerospace, automotive, and medical.

Advantages of In718 Powder:

1. High Strength:

In718 powder is renowned for its high tensile and yield strength, making it perfect for producing components that require strength and durability. This property is particularly important in industries where high performance under extreme conditions is necessary.

2. Corrosion Resistance:

In718 powder has excellent corrosion resistance, making it suitable for use in harsh environments where components are exposed to corrosive substances. This property ensures that parts made from In718 powder have a longer lifespan and require less maintenance.

3. High-Temperature Resistance:

Another key advantage of using In718 powder is its ability to withstand high temperatures without losing its mechanical properties. This makes it a popular choice for components that are exposed to elevated temperatures, such as those used in aerospace engines.

Read more about inconel 718 price here.

Applications of In718 Powder:

Due to its exceptional mechanical properties and high-temperature resistance, In718 powder is commonly used in the production of aerospace components, gas turbine engine parts, and medical implants. Additive manufacturing processes using In718 powder have revolutionized the way these components are produced, allowing for faster and more cost-effective manufacturing methods.

In conclusion, the use of In718 powder in additive manufacturing offers numerous advantages, including high strength, corrosion resistance, and high-temperature resistance. Its versatility and reliability make it a popular choice for a wide range of industries looking to produce high-quality components efficiently.

Leave a Reply